Technicial Specifications

| Net Power - ISO 9249 | 196 kW |

| Engine Model | Cat C9.3B |

| Stroke | 149 mm |

| Displacement | 9.3 l |

| Rated Net Power - 2,200 rpm - ISO 9249 | 196 kW |

| Rated Gross Power - 2,200 rpm - ISO 14396 | 219 kW |

| Max Net Torque - 1,200 rpm - ISO 14396 | 1671 N·m |

| Bore - ISO 9249 | 115 mm |

| Max Gross Power - 1,600 rpm - ISO 14396 | 239 kW |

| Max Gross Torque - 1,200 rpm - ISO 14396 | 1779 N·m |

| Operating Weight | 21577 kg |

| Bucket Capacities | 3.8-7.1 m³ (5.0-9.25 yd³) |

| Forward - 1 | 6.4 km/h |

| Forward - 2 | 12.1 km/h |

| Forward - 3 | 21 km/h |

| Forward - 4 | 34.8 km/h |

| Reverse - 1 | 7 km/h |

| Reverse - 2 | 13.2 km/h |

| Reverse - 3 | 23 km/h |

| Reverse - 4 | 36.9 km/h |

| Note (1) | Maximum travel speeds (26.5R25 tires). |

| Note (2) | Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 825 mm (32.5 in) roll radius. |

| Brakes | Brakes meet ISO 3450:2011 standards |

| Steering System - Pump Type | Piston |

| Hydraulic Cycle Time - Raise from Carry Position | 6.5 s |

| Hydraulic Cycle Time - Total Cycle Time | 12 s |

| Hydraulic Cycle Time - Lower, Empty, Float Down | 2.8 s |

| Implement System - Maximum Operating Pressure | 27900 kPa |

| Implement System - Maximum Flow 3rd Function | 320 l/min |

| Implement System - Maximum Operating Pressure 3rd Function | 23500 kPa |

| Implement System - Maximum Flow - 2,200 rpm | 320 l/min |

| ROPS/FOPS | ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards |

| Operating Weight | 21577 kg |

| Breakout Force | 164 kN |

| Note (1) | For 4.0 m³ (5.2 yd³) general purpose bucket with BOCE. |

| Note (3) | **Compliance to ISO 14397-1:2007 Sections 1 thru 5. |

| Note (2) | *Full compliance to ISO 14397-1:2007 Sections 1 thru 6, which requires 2% verification between calculations and testing. |

| Tipping Load - Full Turn - Rigid Tires** | 14568 kg |

| Tipping Load - Full Turn - ISO 14397-1:2007* | 13594 kg |

| With Cooling Fan Speed at Maximum Value - Operator Sound Pressure Level (ISO 6396:2008) | 75 dB(A) |

| Note (2) | **European Union Directive “2000/14/EC” as amended by “2005/88/EC.” |

| Note (1) | *For machines in European Union countries and in countries that adopt the “EU Directives.” |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Power Level (ISO 6395:2008) | 110 dB(A) |

| With Cooling Fan Speed at 70% of Maximum Value - Operator Sound Pressure Level (ISO 6396:2008)* | 75 dB(A) |

| With Cooling Fan Speed at 70% of Maximum Value - Exterior Sound Power Level* | 108 LWA** |

| Differential - Final Drives - Front | 57 l |

| Fuel Tank | 320 l |

| Crankcase | 25 l |

| Cooling System | 53 l |

| Transmission | 55 l |

| Differential - Final Drives - Rear | 57 l |

| Hydraulic Tank | 120 l |

| Hydraulic Cycle Time - Dump, at Maximum Raise | 2.7 s |

| Choices | Choices include: Triangle 26.5-25 20PR L3 (TL612); Triangle 26.5R25, L3 (TB516); Maxam 26.5R25, L3 (MS302); Bridgestone 26.5R25, L3 (VJT); Maxam 26.5R25, L5 (MS503); Bridgestone 26.5R25, L5 (VSDT); Triangle 26.5R25, L5 (TL538S+) |

| Lift Arm Clearance | 3705 mm |

| B-Pin Height | 4256 mm |

| Centerline of Rear Axle to Edge of Counterweight | 2453 mm |

| Height - Top of ROPS | 3582 mm |

| Height - Top of Exhaust Pipe | 3539 mm |

| Height - Top of Hood | 2804 mm |

| Ground Clearance | 455 mm |

| Wheel Base | 3550 mm |

| Centerline of Rear Axle to Hitch | 1775 mm |

| Rack Back - Maximum Lift | 62 ° |

| Rack Back - Carry | 50 ° |

| Rack Back - Ground | 42 ° |

Advantages and Features

Proven Reliability

- Cat C9.3B engine offers high power density with a combination of proven and improved electronic, fuel, and air systems.

- Engine meets China Nonroad Stage III and Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- Thorough component choice, design and in-machine validation processes result in excellent reliability and uptime.

- Advansys™ GET system features stronger adapters; tips with a new shape to better protect the adapter and an integrated retainer.

Achieve Greater Productivity

- The proven Cat Z-bar linkage geometry with Performance Series Buckets offer excellent penetration into the pile and high breakout forces. This results in low fuel consumption and exceptional production capabilities.

- Cat designed, electronically controlled, automatic powershift heavy duty planetary transmission features shift protection and single clutch gear shifting for efficiency, durability, and smooth gear changes.

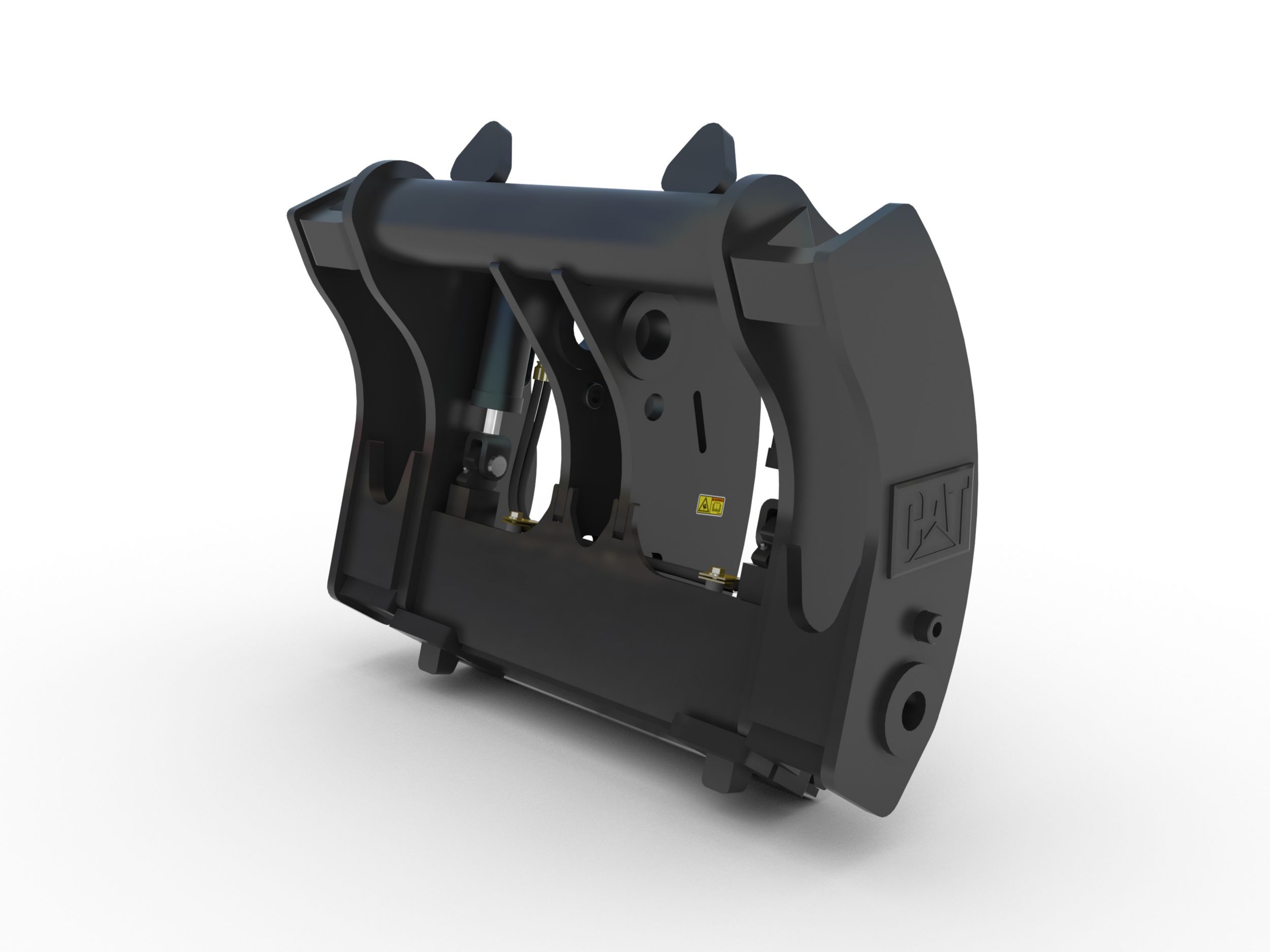

- Optional Fusion™ quick-coupler and third hydraulic function can make the machine a versatile tool carrier for buckets, grapples or forks.

Superior Fuel Efficiency

- Engine Idle Management System (EIMS) reduces idle RPM and fuel consumption.

- Variable speed fan adjusts to meet the varying cooling requirements of the machine resulting in a reduced average fan speed and lowered fuel consumption, noise levels, and radiator plugging.

- Load sensing hydraulics produce flow and pressure for the implement system upon demand and only in amounts necessary to perform the needed work functions.

Easy, Comfortable Operator Environment

- The spacious cab features easy, intuitive controls and excellent visibility which provides a comfortable working environment for efficient operation.

- A comfortable cloth covered suspension (mechanical) seat is standard, an optional air suspended seat is available.

- Pilot-operated hydraulic implement controls deliver comfortable, low-effort operation. Two single-axis levers or one joystick are available. Both arrangements are equipped with kick-down switches.

- Unmatched viewing area with a wide, flat, and distortion-free front windshield.

- The glass stretches to the floor of the cab for excellent visibility to the bucket and front tires.

- Sliding side windows on both sides allow natural ventilation and easy communication to ground staff.

- The cab roof has channels which direct rain off the corners of the cab, keeping windows clear.

- Air conditioning and heating systems are standard. Ten louvered vents allow the operator to direct the air flow to remain productive and efficient all shift long.

- Optional windshield guard.

Safety Features

- Ladders are standard on both sides of the machine; the main cab access features a 15-degree angle to easily access the operator environment.

- Steps are equipped with hand and/or guardrails to safely access the cab and maintenance points of the machine.

- The main cab door opens to the front and provides wide access to the operator environment.

- Front and back wipers ensure that a clear view is maintained.

- External rearview mirrors with integrated spot mirrors are standard.

- A rear vision camera is standard to enhance visibility behind the machine.

Reduced Maintenance Time and Costs

- Grouped service points and sight gauges allow for easy daily maintenance.

- Convenient access to left, right, and rear of engine compartment provides excellent serviceability.

- Electrical service center, along with additional key serviceability features, help make servicing and in-field component exchange quick, easy, and efficient.

- A rear swing-up grill gives easy cleaning access to the cooling cores.

- Hinged wheel guards are easy to remove/re-install providing wide access to all maintenance points and to the engine compartment.

- Optional power train bottom guard protects the machine against damage to reduced downtime.

- Optional Cat Autolube system provides full lube system monitoring and diagnostic test visibility. One-button control, including fault flash function.

- Caterpillar design and manufacturing techniques assure outstanding service life.

Cat Production Measurement Kit – Optional*

- On-the-go weighing** for precise load targets with proven accuracy, flexible installation, and easy calibration and setup.

- Brings payload weighing to the cab so operators can work more productively and deliver consistently accurate loads.

- Increases productivity, weighing while lifting with no interruptions in loading cycle.

- High efficiency: load to exact specification, load more trucks faster, and move more material for more revenue.

- Improve efficiency with less rework; save time, labor, fuel, and costs.

- Simple installation.

**Not legal for trade

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

OPERATOR ENVIRONMENT

- Air conditioning (HVAC) with 10 vents and filter unit located outside of cab

- Bucket/work tool function lockout

- Switch, transmission neutralizer lockout

- Cab, pressurized and sound suppressed

- Camera, rearview

- Coat hook

- Computerized monitoring system

- Cup holders and personal tray on right console and behind seat

- Heater and defroster

- Horn

- Mirrors, rearview external

- Pilot hydraulic controls, lift and tilt function; two (2) single axis levers or joystick

- 12V power port (10A)

- Radio ready

- ROPS/FOPS structure

- Seat, Cat Comfort (cloth), mechanical suspension

- Steering column, adjustable angle

- Window, sliding (left and right sides)

- Wipers/washers (front and rear)

-

POWER TRAIN

- Brakes, full hydraulic enclosed wet-disc

- Cat C9.3B equivalent to Tier 3

- EIMS (Engine Idle Management System)

- Fan, radiator, electronically controlled, hydraulically driven, temperature sensing, on demand

- Filter, fuel primary/secondary/tertiary

- Filters, engine air, primary/secondary

- Fuel priming pump (electric)

- Fuel/water separator

- Muffler, sound suppressed

- Radiator, unit core (9.5 fpi) with ATAAC

- Torque converter

- Transmission, automatic, power shift (4F/4R), kick-down function, overspeed protection

-

LINKAGE

- Lift and bucket return-to-dig kickouts (electro‑magnetic), mechanical adjustment

- Z-bar, cast tilt lever

-

HYDRAULICS

- Dedicated brake and fan piston pump

- Dedicated load sensing steering pump

- Load sensing implement system pilot operated

- S O·SSM oil sampling valves

-

ELECTRICAL

- Alarm, back-up/main disconnect switch

- Alternator (115-amp, brush type)

- Batteries, maintenance free (2×1,125 CCA)

- Ignition key; start/stop

- Lighting system: 4 halogen work lights, cab mounted

- Lighting system: 2 halogen work lights, loader tower mounted

- Starter, electric (heavy duty)

- Starting and charging system, 24V

-

ADDITIONAL EQUIPMENT

- Counterweight, 700 kg (1,545 lb)

- Fenders (front and rear) steel

- Grill, airborne debris

- Hitch, drawbar with pin

- Hood, non-metallic on steel structure

- Doors, service access (locking)

- L3 bias or radial tires

- Product Link™ ready

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

OPERATOR ENVIRONMENT

- Radio

- Seat, air suspended

- Steering, secondary, electrical

-

POWER TRAIN

- Fan, reversing automatic and manual control

-

LINKAGE

- Fusion quick coupler control

-

HYDRAULICS

- Quick coupler control

- Ride control

- 3rd function with additional dedicated single axis lever

-

ELECTRICAL

- Lighting system: 8 halogen work lights, cab mounted

- Lighting system: 4 LED work lights, cab mounted

- Lights: warning beacon

- Roading lights with high/low beam and F and R turn signals

-

ADDITIONAL EQUIPMENT

- Autolube system

- Cold weather starting basic (ether starting aid)

- Cold weather starting full (HD batteries 2×1,400 CCA, ether system, jacket water heater, cold weather fluids)

- Fender extensions or roading

- L5 traction tires

- Power train guard

- Precleaner, turbine

- Toolbox

- Windshield guard

966 GC Key Features and Benefits

Complete 966 GC Key Features and Benefits

966 GC Product Brochure (SE Asia, Indo)

966 GC Wheel Loader Product Brochure (Afr-ME, CIS, S Am, Asia Pacific Excluding SE Asia, Indo Japan, Korea)

966 GC Technical Specifications (Afr-ME, CIS, S Am, Asia Pacific excluding SE Asia, Indo, Japan, Korea)

966 GC Technical Specifications (Afr-ME, CIS, S Am, Asia Pacific excluding SE Asia, Indo, Japan, Korea)

Medium Wheel Loaders - Rigout Catalog

Medium Wheel Loaders - Rigout Catalog