Technicial Specifications

| Engine Model | Cat C3.6 |

| Power - Net | 59.7 kW |

| Displacement | 3.6 l |

| Net Power - 2,200 rpm - SAE J1349 | 59.7 kW |

| Net Power - 2,200 rpm - ISO 9249/EEC 80/1269 | 59.7 kW |

| Note (1) | Net power is tested per ISO 9249:2007 and SAE J1349:2011 and as advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system and alternator. |

| Note (2) | Engine equivalent to Tier 3 emission standards. |

| Operating Weight | 8099 kg |

| Operating Weight - LGP | 8545 kg |

| Operating Weight - LGP, 762 mm/30 in | 8752 kg |

| Note (2) | For machine with ripper, add 554 kg (1,222 lb). |

| Note (1) | Specifications shown are for machine equipped with dozer blade, EROPS cab, back-up alarm, operator, coolant, lubricants and full fuel tank. |

| Drive Pumps | 1 |

| Maximum Travel Speed - Reverse | 10 km/h |

| Relief Valve Settings | 48500 kPa |

| Maximum Travel Speed - Forward | 9 km/h |

| Track Motors | 2 |

| Pump Output | 65 l/min |

| Relief Valve Settings | 20600 kPa |

| Weight | 610 kg |

| Winch Drive | Hydrostatic |

| Control | Hydraulic |

| Speed | Variable |

| Throat Clearance | 171.5 mm |

| Overall Width | 741 mm |

| Drum Capacity - Recommended Cable | 113 m |

| Maximum Line Pull - Full Drum | 11340 kg |

| Drum Capacity - Optional Cable | 78 m |

| Rope Diameter - Recommended | 16 mm |

| Winch Length | 705 mm |

| Maximum Line Pull - Bare Drum | 18144 kg |

| Maximum Line Speed - Bare Drum | 40 m/min |

| Drum Width | 274 mm |

| Drum Diameter | 254 mm |

| Maximum Line Speed - Full Drum | 63 m/min |

| Rope Diameter - Optional | 19 mm |

| Type | Parallelogram |

| Number of Shanks | 3 |

| Height | 165 mm |

| Weight | 554 kg |

| Overall Width | 1710 mm |

| Maximum Reach - Ground Line | 766 mm |

| Maximum Ground Clearance Under Tip | 448 mm |

| Maximum Digging Depth | 337.5 mm |

| Power Train | Hydrostatic |

| FOPS | ISO 3449:2005 Level II |

| ROPS | ISO 3471:2008 |

| Track Gauge | 1495 mm |

| Length - Track on Ground - LGP, 762 mm (30 in) | 2248 mm |

| Shoe Width - Standard | 406 mm |

| Ground Pressure - LGP, 762 mm (30 in) | 25.5 kPa |

| Track Gauge - LGP, 762 mm (30 in) | 1860 mm |

| Length - Track on Ground - LGP | 2248 mm |

| Number of Rollers - Each Side | 6 |

| Shoe Width - LGP, 762 mm (30 in) | 762 mm |

| Track Gauge - LGP | 1725 mm |

| Ground Pressure - LGP | 29.9 kPa |

| Shoe Width - LGP | 635 mm |

| Number of Shoes - Each Side - Sealed and Lubricated Track (SALT) Undercarriage | 43 |

| Length of Track on Ground | 2248 mm |

| Ground Pressure | 44.5 kPa |

| Number of Shoes - Each Side - Abrasion Undercarriage | 38 |

| Crankcase - With Filter | 10.5 l |

| Fuel Tank | 195 l |

| Cooling System | 19 l |

| Final Drive - Each - LGP | 10 l |

| Transmission - Hydraulic Tank | 90 l |

| Final Drives - Each Side | 10 l |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.8 kg of refrigerant which has a CO2 equivalent of 2.574 metric tonnes. |

| Track Gauge - LGP | 1725 mm |

| Overall Length - With Blade - LGP | 4262 mm |

| BLADE: Blade Width - LGP | 3149 mm |

| BLADE: Blade Capacity (SAE) - LGP | 1.99 m³ |

| BLADE: Blade Width at Maximum Angle - LGP | 2874 mm |

| Ground Clearance - LGP, 762 mm (30 in) | 332 mm |

| BLADE: Digging Depth - LGP | 583 mm |

| Track Gauge - LGP, 762 mm (30 in) | 1860 mm |

| Overall Length - With Blade - LGP, 762 mm (30 in) | 4262 mm |

| BLADE: Maximum Angle (either side) - LGP | 25° |

| BLADE: Maximum Tilt - LGP | 438 mm |

| BLADE: Blade Cutting Edge Angle, Adjustable - LGP | 52° to 58° |

| BLADE: Blade Height - LGP | 860 mm |

| Ground Clearance - LGP | 332 mm |

| BLADE: Blade Lift Height - LGP | 730 mm |

| Note | *Abrasion Undercarriage |

| Dozer Height - LGP, 762 mm (30 in) | 2765 mm |

| Width of Dozer (standard shoes, no blade) - LGP | 2360 mm |

| Dozer Height - Standard | 2765 mm |

| Dozer Height - LGP | 2765 mm |

| Width of Dozer (standard shoes, no blade) - Standard | 1900 mm |

| Width of Dozer (standard shoes, no blade) - LGP, 762 mm (30 in) | 2411 mm |

| Overall Length - With Blade - Standard | 4273 mm |

| BLADE: Maximum Tilt - Standard | 368 mm |

| BLADE: Blade Capacity (SAE) - Standard | 1.52 m³ |

| BLADE: Blade Width - Standard | 2646 mm |

| Track Gauge - Standard | 1495 mm |

| Ground Clearance - Standard | 332 mm |

| BLADE: Blade Width at Maximum Angle - Standard | 2417 mm |

| BLADE: Digging Depth - Standard | 589 mm |

| BLADE: Blade Height - Standard | 910 mm |

| BLADE: Blade Lift Height - Standard | 730 mm |

| BLADE: Maximum Angle (either side) - Standard | 25° |

| BLADE: Blade Cutting Edge Angle, Adjustable - Standard | 52° to 58° |

| Rope Diameter - Recommended | 0.6 in |

| Weight | 794 kg |

| Drum Capacity - Recommended Cable | 84 m |

| Winch Drive | Hydraulic |

| Maximum Line Pull - Full Drum | 9231 kg |

| Maximum Line Speed - Bare Drum | 15 m/min |

| Rope Diameter - Optional | 19 mm |

| Maximum Line Speed - Full Drum | 24 m/min |

| Maximum Line Pull - Bare Drum | 14583 kg |

| Speed | Variable |

| Control | Hydraulic |

| Drum Capacity - Optional Cable | 59 m |

| Drum Diameter | 203.2 mm |

| Winch Length | 35.63 in |

| Drum Width | 9.65 in |

| Overall width | 709 mm |

| Throat Clearance | 141.4 mm |

Advantages and Features

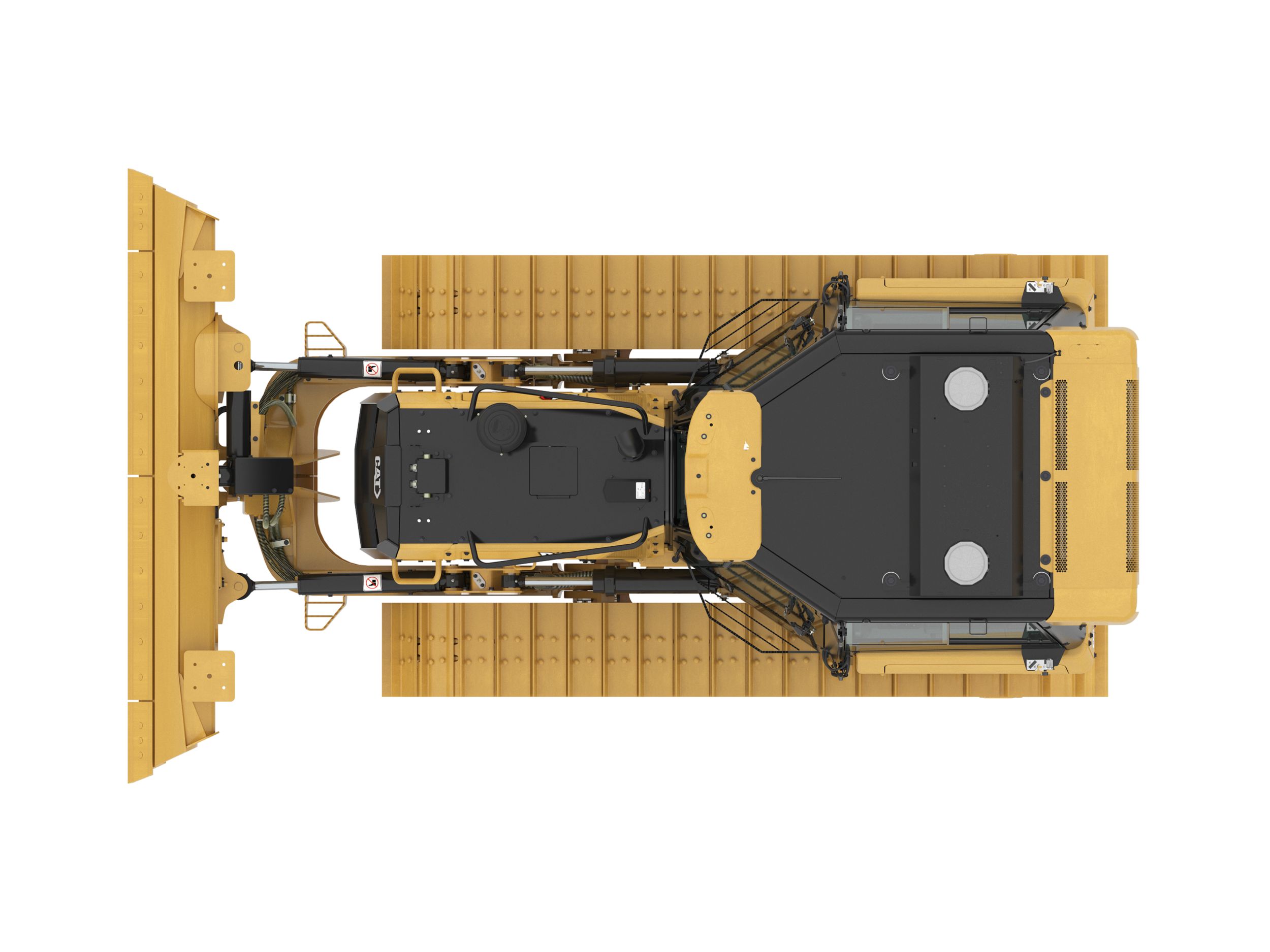

IMPROVED VISIBILITY

- New sloped hood provides better visibility to the work in front of the blade as well as the overall job site. Better visibility can equal less operator fatigue and more confidence in your work.

GRADE TECHNOLOGY

-

Cat small dozers include a suite of Operator Assist features that work seemlessly to save time, effort, fuel, machine wear and overall costs. Cat Grade with Assist is an optional technology available for small dozers.

- Steer Assist automates track steering with light or heavy loads and automates blade tilt steering to help push heavy loads with less effort. This feature helps reduce operator inputs by up to 75% and enhances operator efficiency and productivity. Steer Assist is standard with Assist with Attachment Ready Option (ARO). Steer Assist 3D is standard with Grade 3D with Assist.

- Stable Blade Lift and Tilt automatically works behind the scenes to allow operators to create smooth surfaces with less effort using accelerometers on the blade and chassis with an advanced algorithm to make minor blade raise and lower movements. Stable Blade Lift and Tilt is standard with Assist with ARO and Grade 3D with Assist.

- Blade Load Monitor provides real-time feedback of current load vs. target load to fully utilize machine capacity benefiting operators of all skills levels. Automatically compensates for ground conditions. This feature is not available indoors or in areas where a GPS signal is not available. Blade Load Monitor is standard with Assist with ARO and Grade 3D with Assist.

- Low Slip Traction Control prevents excessive track slip to improve machine efficiency and reduce burden on the operator. Feature offers two modes: Normal Mode helps when pushing heavy blade loads by limiting non-productive track slip, recommended for most applications. And Low Slip Mode limits track slip for applications sensitive to slip such as spreading material on top of a liner, select this mode when needed. Traction Control is standard with Assist with ARO and Grade 3D with Assist.

- AutoCarry™ raises and lowers the blade to maximize pushing capability and prevent excessive track slip when pushing heavy loads. Feature is designed to work in unison with other Operator Assist Features. Not available indoors or in areas where a GPS signal is not available. AutoCarry is standard with Assist with ARO and Grade 3D with Assist.

- Scalable 2D and 3D Cat Grade is an optional feature that makes your job up to 39% faster with up to 82% fewer operator inputs and less rework by maintaining blade angles for better surface quality – even with less experienced operators.

- Cat Command remote control is an optional feature that takes you off the machine and away from hazardous conditions, dust, noise or vibration or operating on unstable surfaces. Eliminates risk of injury from climbing on or off the machine. Integrated with dozer systems, Cat Command enables smooth, precise control with access to all machine functions and advanced features (if equipped) for maximum efficiency and productivity. Availability varies by region.

UP TO 10% IMPROVED FUEL ECONOMY

- The D1 features the lowest fuel consumption in this size class with the same great performance you've come to expect. Up to 20% improvement and no performance sacrifice when ECO mode is active.

COMFORTABLE WORK SPACE

- The spacious and comfortable cab features an optional heated and ventilated seat, along with heated joystick controls to make the operator comfortable no matter what the conditions are outside. The seat height and armrests can be easily adjusted to the operator’s preference.

BIGGER, BETTER DISPLAY WITH CAMERA

- This new and improved optional 10 in (254 mm) touchscreen, color display is easy to use, with a great view of machine settings, rearview camera and Slope Indicate/Slope Assist screens. The large reversing camera gives the operator better visibility to the job site.

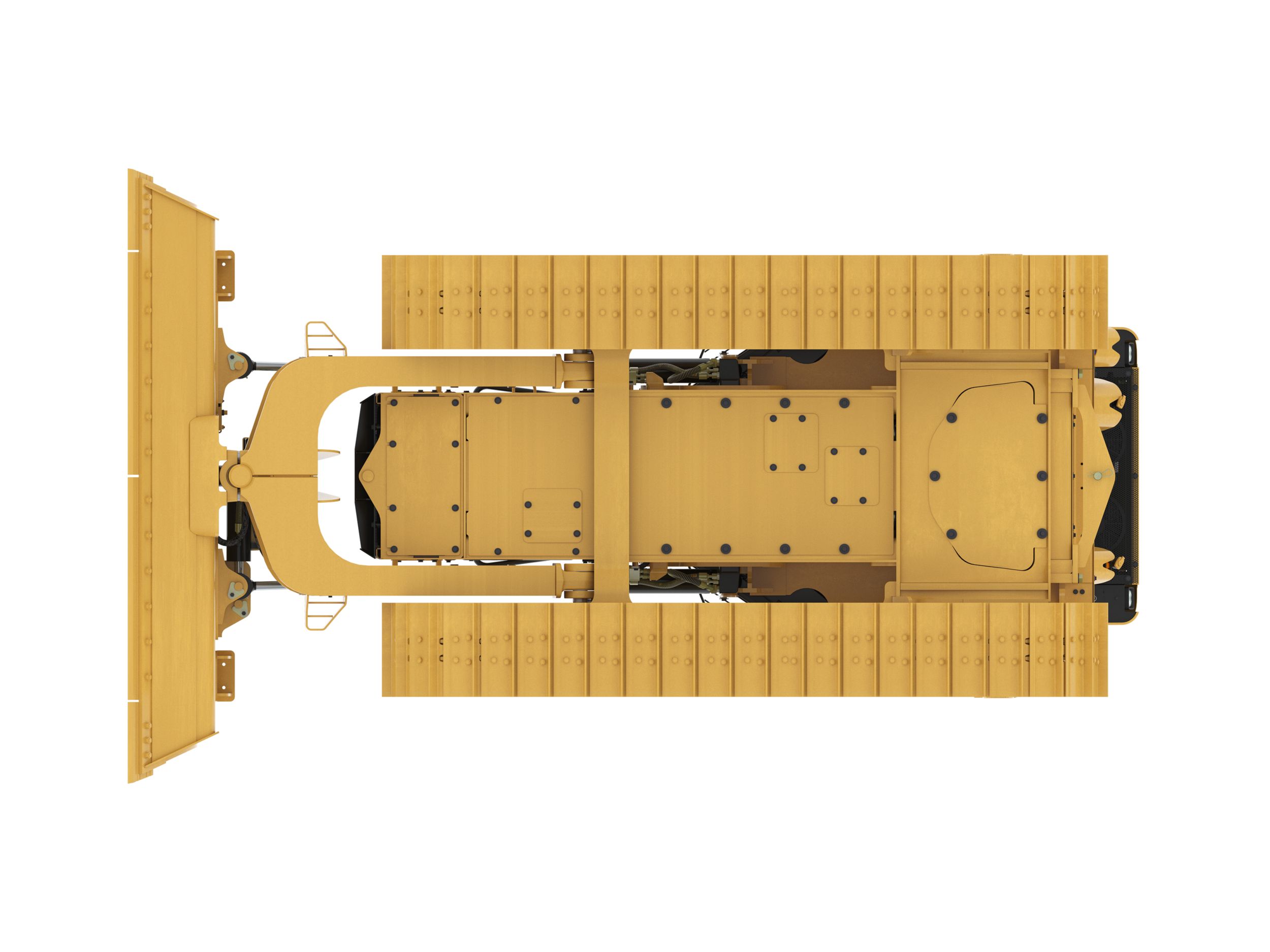

DURABLE UNDERCARRIAGE

- The D1 is available with either a Heavy Duty (HD) or Abrasion undercarriage to best suit your application. The undercarriage has a longer life resulting in less down time. A one piece mainframe/track roller frame design and the large, double reduction planetary final drive allow the machine to push heavy loads.

Standard Equipment

-

POWER TRAIN

- Air cleaner with precleaner, automatic dust ejection and underhood intake

- Aluminum bar plate cooling system (radiator, power train)

- Automatic traction control

- Cat C3.6 diesel engine

- Drive, auxiliary

- Dual path, closed loop, hydrostatic transmission

- Electric fuel pump

- Fuel/water separator

- Turbocharged aftercooled

-

ELECTRICAL

- Alarm, backup

- Alternator, 150 amp, heavy duty

- Batteries, heavy duty, maintenance free, 1,000 CCA

- Diagnostic connector

- Four integrated front halogen lights, two rear halogen

- Horn, electric

- Starter, electric, 12 V, heavy duty

-

UNDERCARRIAGE

- SALT undercarriage (43 section)

- Carrier rollers

- Guards, front/rear guiding

- Six roller track frame

- Track adjusters, hydraulic

- Track rollers, lifetime lubricated

-

HYDRAULIC

- Hydraulic pump and oil

- Single lever, three function control

- Three valve hydraulics

-

CAT TECHNOLOGY

- Stable Blade – Basic Lift

- Third party 3D grade system compatible

- Slope Indicate

- Cat Product Link™ PLE643/PLE743 Cellular

-

ATTACHMENTS

- Rigid drawbar

- Front pull device

-

OPERATOR ENVIRONMENT

- Armrests, adjustable

- Coat hook

- Controls, seat mounted, fore/aft adjustment

- Cup holders

- Eco mode

-

Electronic Monitoring system with gauge:

– Chassis slope indication

– Engine coolant temperature

– Fuel level

– Hydraulic oil temperature

- Electronic security system

- Engine air cleaner service indicator

- Engine RPM and gear display

- Floor mat, rubber, heavy duty

- Foot pads, dash

- Hour meter, electronic

- Independent forward/reverse speed settings

- Mirror, rearview, inside

- Power port, 12 volt

- ROPS/FOPS canopy

- Seat, air suspended, cloth or vinyl

- Seatbelt, hi-vis retractable 76 mm (3")

- Seatbelt buckling indicator/reminder

- Single pedal combining decel and brake functions

- Speed recall

- Storage compartment

- Throttle switch, rotary

- Travel speed limiter, electronic

Optional Equipment

-

POWER TRAIN

- Air cleaner with external precleaner

- Installation, winch

-

ELECTRICAL

- Cat Command Station (availability varies by region)

-

UNDERCARRIAGE

- Abrasion undercarriage (38 section)

-

Track Pairs

– Track, 406 mm (16 in)

– Track, 635 mm (25 in)

– Track, 762 mm (30 in)

-

HYDRAULIC

- Four valve for use with ripper

- Four valve for use with winch

-

CAT TECHNOLOGY

-

Assist with Attachment Ready Option (ARO) includes:

– Slope Indicate

– Blade Load Monitor

– Stable Blade Lift and Tilt

– Slope Assist

– Traction Control

– Steer Assist

– AutoCarry

-

Grade 3D with Assist includes:

– Same Assist with ARO features

– Steer Assist 3D

– Grade 3D

- Cat Product Link PLE683/PLE783 Cellular/Satellite

- Full-color 254 mm (10 in) touchscreen grade display

- Cat Command Console (availability varies by region)

-

Assist with Attachment Ready Option (ARO) includes:

-

ATTACHMENTS

- Drawbar, towing

- Machine security system

- Mounting, winch

- Ripper, parallelogram, includes three shanks and teeth

- Winch, hydraulic, high performance

- Winch, hydraulic, retrieval

-

OPERATOR ENVIRONMENT

- Cab, with air conditioning

- Cab, polycarbonate windows and air conditioning

- Radio, AM/FM Bluetooth®

-

Seat, air suspension, choice of:

– Vinyl, heated seat with heated controls

– Cloth, heated seat with heated controls

– Cloth, heated and ventilated seat with heated controls

- Sound suppression

-

OTHER

- Heater, engine, coolant 120 V/240 V

- Starting aid, ether

D1 Small Product Brochure

D1 Small Product Brochure

D1, D2, D3 Shiphold Product Brochure

D1, D2, D3 Shiphold Product Brochure

D1, D2, D3 Fire Suppression Dozers Product Brochure (N Am, Aus-NZ)

D1, D2, D3 Fire Suppression Dozers Product Brochure (N Am, Aus-NZ)

Options and Accessories Kit Guide for Small Track Type Tractors

Options and Accessories Kit Guide for Small Track Type Tractors