Technicial Specifications

| Engine Model | Cat C9 |

| Power - Net | 148 kW |

| Biodiesel Capability | Up to B100* |

| Note (1) | Net power advertised is the power available at the flywheel when engine is equipped with a fan at maximum speed, air cleaner, muffler, alternator. Advertised power is tested per the specified standard in effect at the time of manufacture. |

| Note (2) | *Cat engines are compatible with the following renewable, alternative, and bio-fuels** with lower greenhouse gas emission impact: Up to B20 biodiesel (FAME)***, up to 100% HVO and GTL renewable fuels. **Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. ***Up to B100 capable when equipped with optional B100-compliant fuel lines. Please consult the Operations and Maintenance Manual (OMM) for further information. |

| Operating Weight | 18984 kg |

| Operating - D6R2 (S) | 18984 kg |

| Operating - D6R2 (SU) | 19066 kg |

| Operating - D6R2 (A) | 19448 kg |

| Operating - D6R2 XL (SU) | 19914 kg |

| Operating - D6R2 XL (A) | 19969 kg |

| Operating - D6R2 LGP (S) | 21661 kg |

| Emissions | China Nonroad II, equivalent to U.S. EPA Tier 2/ EU Stage II |

| Standard - Net Power - Rated - ISO 9249/SAE J1349 | 141 kW |

| Standard - Net Power - Rated - ISO 9249 (DIN) | 192 mhp |

| XL/LGP - Net Power - Rated - ISO 9249/SAE J1349 | 158 kW |

| XL/LGP - Net Power - Rated - ISO 9249 (DIN) | 215 mhp |

| Emissions | China Nonroad III, equivalent to U.S. EPA Tier 3/ EU Stage IIIA |

| Standard - Net Power - Rated - ISO 9249/SAE J1349 | 162 kW |

| Standard - Net Power - Rated - ISO 9249 (DIN) | 220 mhp |

| XL/LGP - Net Power - Rated - ISO 9249/SAE J1349 | 176 kW |

| XL/LGP - Net Power - Rated - ISO 9249 (DIN) | 239 mhp |

| Fuel Tank | 424 l |

| Ground Pressure - A-Blade (ISO 16754) | 64 kPa |

| Ground Pressure - SU - Blade (ISO 16754) | 61 kPa |

| Ground Pressure - SLGP - Blade (ISO 16754) | 35 kPa |

| S-Blade Capacity | 4 m³ |

| SU - Blade Capacity | 5.6 m³ |

| A-Blade Capacity | 4 m³ |

| SU XL - Capacity | 5.6 m³ |

| A XL - Capacity | 4 m³ |

| S-Blade Capacity - LGP | 3.8 m³ |

| S-Blade Width | 3360 mm |

| SU - Blade Width | 3260 mm |

| A-Blade Width | 4166 mm |

| SU XL - Width | 3260 mm |

| A XL - Width | 4166 mm |

| S-Blade Width - LGP | 4063 mm |

Advantages and Features

DESIGNED FOR OPERATORS

- Comfortable, quiet cab offers excellent all-around visibility.

- Pressurization helps reduce dust in the cab, and a standard suspension seat offers multiple adjustments for greater operator comfort.

- The instrument panel has easy-to-read gauges so you can monitor fuel levels, engine speed, temperature levels and more. Lights and/or alarms keep operators informed about conditions like restrictions to engine intake air, power train or fuel filters or water in the fuel.

- Ergonomic, low-effort implement and steering controls offer simple, precise operation. Use a single handle tiller bar for direction changes and to select gears with the touch of a button.

- Implement Lock-Out prevents inadvertent operation of hydraulic attachments.

- Optional Auto Shift automatically down shifts to the most efficient gear based on load to save fuel and increase productivity.

- Use optional bi-directional control to dial in preselected forward/reverse gears for reduced effort and improved efficiency.

PERFORMANCE AND PRODUCTIVITY

- Cat C9 engine gives you the power you need to doze through tough material.

- Differential Steering increases the speed of one track while slowing the other one down to give you exceptional turning, even with a full blade load.

- A single stage torque divider sends 70 percent of engine torque through a converter and the other 30 percent through a planetary gear set so you get more power to the ground.

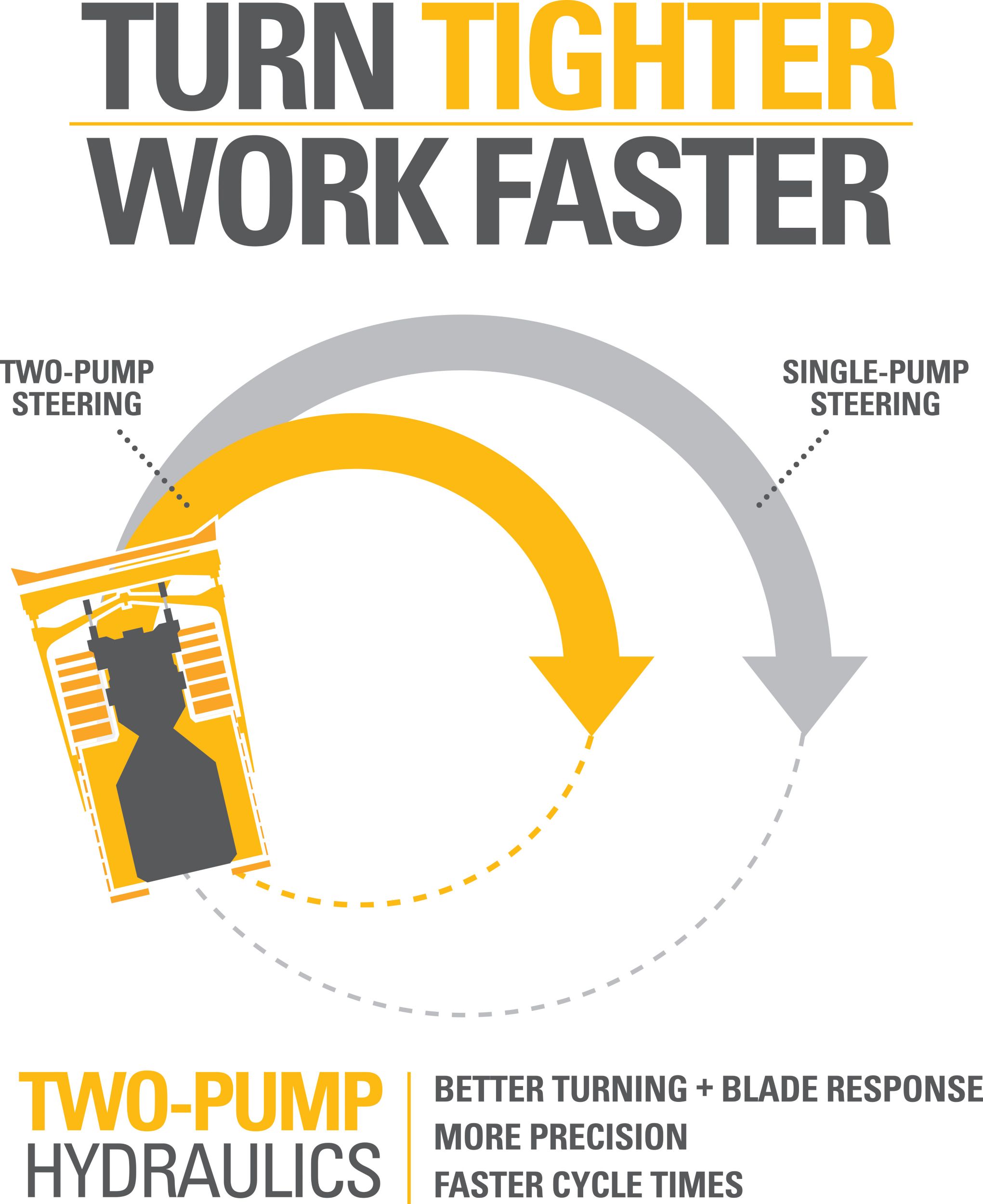

- Two-pump hydraulic system means you can count on simultaneous blade response and steering performance. This gives you more precision and maneuverability that is especially beneficial when working in close quarters or land clearing.

- Load Sensing Hydraulics continuously adjusts hydraulic power to maximize your efficiency.

- Efficient aluminum bar plate cooling system gives you the cooling capability to handle high ambient conditions.

- Forestry, Waste and Cold Weather arrangements offer added features and guarding to take on especially harsh environments.

BUILT FOR LONG TERM PRODUCTION

- Caterpillar elevated sprocket design isolates final drives from ground induced impacts.

- Choose Standard, XL or LGP configuration to best match conditions and applications.

- Choice of Heavy Duty or Cat Abrasion undercarriage to optimize for your application.

- The foundation of every Cat dozer is a rugged mainframe built to absorb high impact shock loads and twisting forces.

- Pinned pivot shafts connect the mainframe and roller frames for independent oscillation. This gives you added strength and ground clearance, plus allows the dozer to better follow ground contours for maximum traction and operator comfort.

- High efficiency fuel filters with water-in-fuel sensors add to fuel system robustness.

- Updated design places the alternator in an elevated location for added protection, especially in wet, sandy conditions.

EQUIPPED FOR THE JOB

- From high strength bulldozer blades to a variety of rear attachments, you can outfit your dozer the way you need it.

- L-shaped push arms bring the blade closer to the machine for better balance, maneuverability and blade penetration.

- The added lateral stability and better cylinder positions offers constant pryout capability regardless of blade height.

- The trunnion joint design requires no adjustments to keep the blade tight.

- Dozer blades are manufactured from high tensile strength steel, with a robust multi-cell design to stand up to the most severe applications.

- Semi-Universal, Straight and Angle Blades are available, as well as specialty blades for landfill and land clearing applications.

- Outfit your dozer with a three-shank ripper with curved or straight ripper shanks.

- Rear counterweights optimize balance for backing up steep slopes or increasing performance in heavy dozing applications.

- Choose a drawbar for towing and recovery or outfit your dozer with a winch.

BECAUSE UPTIME COUNTS

- Designed for ease of repair and maintenance. You spend less time on service and more time on the job.

- Service points are grouped and sight gauges let you inspect fluid levels at a glance.

- High efficiency fuel filters have water sensors to enhancing uptime.

- Air conditioning condenser package mounted on top of the cab, increasing capability, while improving engine cooling and serviceability.

- Cat remanufactured parts and Cat certified rebuilds to give a second or even third life to your machine. They incorporate the latest engineering updates so you end up with a like-new dozer and a new machine warranty.

- Product Link™ collects machine data that can be viewed online through web and mobile applications.

- Access information anytime, anywhere with VisionLink® and use it to make informed decisions that boost productivity, lower costs, simplify maintenance, and improve safety and security on your job site.

PURPOSE BUILT SPECIALTY MODELS

- Forestry Arrangement is available with optional machine protection like sweeps, screens and added guarding to help protect the machine in harsh conditions. Cooling system is designed for high debris environments, with easy access for cleanout.

- Cold Weather package features reversible fan and heavy-duty battery/alternator for cold starting. Arctic cab with dual pane glass, as well as optional heated suspension seat, offer greater operator comfort in extreme cold. Solid hood gives added protection against snow and ice, and oils and final drive seals are designed to stand up to cold conditions.

- Waste Handler/LandfillArrangement offers specialized guarding, striker bars and seals help protect the machine from impact and airborne/wrapping debris. Cooling is designed for high debris environments and easy cleanout. Specialized air handling features help deliver cleaner air to the machine. Landfill blades and center-hole track shoes help optimize your waste handler for the job.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWER TRAIN

- Cat C9 turbocharged direct injection diesel engine

- Air cleaner, precleaner with strata tube dust ejector

- Air filter with electronic service indicator

- Aluminum bar plate Air to Air After- Cooler (ATAAC)

- Direct drive fan blower

- Electric fuel priming pump

- Final drives, 3-planet single reduction planetary

- Planetary transmission, electronic power shift 3F/3R speeds

- Prescreener

-

OPERATOR ENVIRONMENT

- Adjustable armrest

- Adjustable contour suspension seat

- Cab with integrated ROPS

- Retractable 76 mm (3 in) seat belt

-

ELECTRICAL

- Halogen lights (4)

-

UNDERCARRIAGE

- Heavy Duty sealed and lubricated track

-

SERVICE AND MAINTENANCE

- Diagnostic connector

- Sampling ports

-

TECHNOLOGY PRODUCTS

- Cat Product Link ready

- Cat Product Link, Cellular PL641

-

GUARDS

- Bottom guards

- Engine cover with perforated hood and side enclosures

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWER TRAIN

- Radiator core protector

- Radiator fan, ejector

- Radiator fan, increased speed (high ambient)

- Radiator fan, reversible (cold weather)

- Raised precleaner

- Turbine precleaner with screen

-

OPERATOR ENVIRONMENT

- Arctic cab with integrated ROPS

- Canopy with integrated ROPS

- Suspension seat, cloth cover

- Suspension seat, cloth cover, heated and ventilated

- Suspension seat, vinyl cover

-

ELECTRICAL

- Halogen lights (4 - sweep)

- Halogen lights (6)

- Halogen lights (8 - sweep)

- LED lights (6)

-

UNDERCARRIAGE

- Cat Abrasion (XL and LGP)

- Waste handing/landfill (XL and LGP)

-

SERVICE AND MAINTENANCE

- Ecology drains, power train

- High speed oil change system

-

TECHNOLOGY PRODUCTS

- Cat Product Link, Satellite PL631

-

BLADES

- Angle blade, hydraulic or mechanical tilt (STD and XL)

- Angle blade, hydraulic or mechanical tilt, land clearing (XL)

- Semi-Universal blade, hydraulic tilt (STD and XL)

- Semi-Universal blade, hydraulic tilt, land clearing (STD and XL)

- Semi-Universal blade, hydraulic tilt, landfill (XL)

- Straight blade, hydraulic tilt (STD and LGP)

- Straight blade, hydraulic tilt, landfill (LGP)

-

ATTACHMENTS

- Multi-shank ripper, straight or curved shanks (3)

- Rear counterweight

- Rigid drawbar

- Ripper hydraulics

- Striker bar, rear (XL or LGP)

- Striker bars, front (XL or LGP)

-

GUARDS

- Forward protection sweeps

- Fuel tank guard

- Heavy duty bottom guard

- Heavy duty radiator guard

- Hydraulic blade tilt line guards

- Land clearing guards

- Solid hood engine enclosure

- Transmission guard

-

SPECIAL ARRANGEMENTS

- Waste Handler

- Forestry/Land Clearing

- Arctic