Technicial Specifications

| Standard - Operating Weight | 13135 kg |

| Static Linear Load | 33 kg/cm |

| Maximum Operating Weight | 13785 kg |

| Standard Compaction Width | 2130 mm |

| Drum Offset | 170 mm |

| Curb Clearance | 723 mm |

| Ground Clearance | 292 mm |

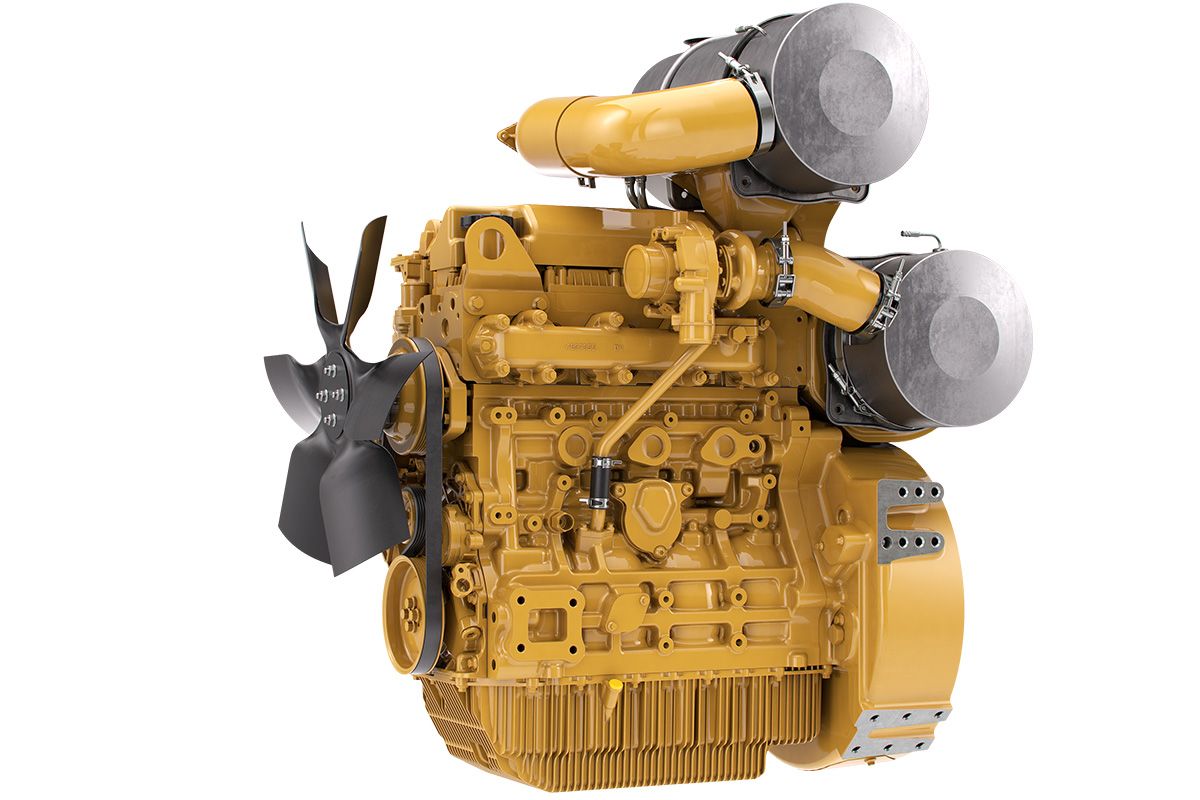

| Engine Model | Cat_C4.4 |

| Gross Power | 106 kW |

| High | 13 km/h |

| Low | 7 km/h |

| Overall Length | 4742 mm |

| Wheel Base | 3450 mm |

| Height - With ROPS/FOPS | 3068 mm |

| Overall Width | 2325 mm |

| Centrifugal Force per Drum - Maximum | 138.2 kN |

| Centrifugal Force per Drum - Minimum | 55.2 kN |

| Maximum Amplitude | 1.03 mm |

| Minimum Amplitude | 0.3 mm |

| Maximum Frequency | 42 Hz |

| Minimum Frequency | 42 Hz |

| Vibration Selection | Independent per drum, front only, rear only, both |

| Fuel Tank Capacity | 250 l |

| Water Spray Tank Capacity | 1000 l |

Advantages and Features

Simple to Operate, Easy to Learn

- Innovative hand-wheel steering technology delivers precise control and good forward visibility

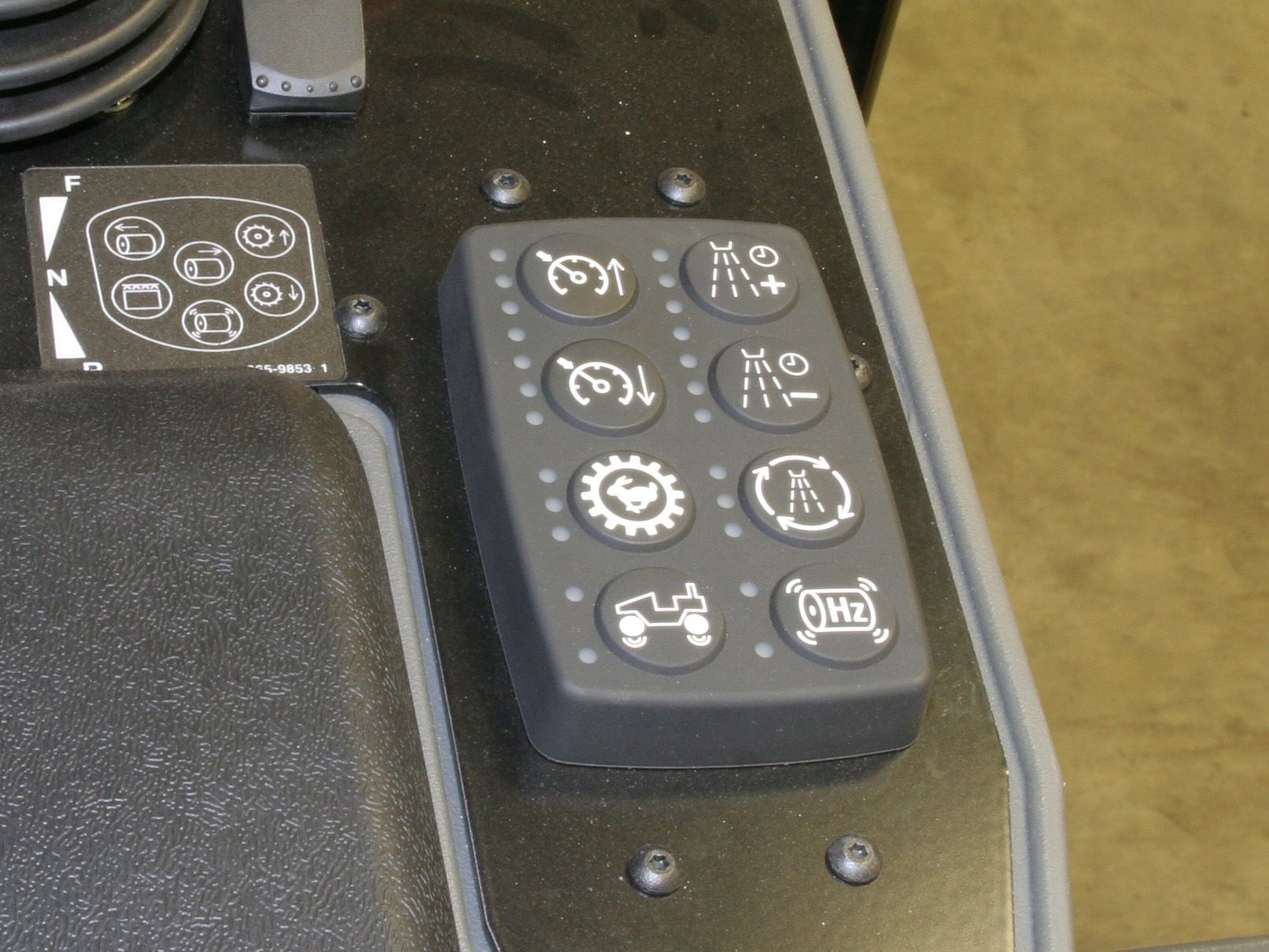

- Easily activate the vibratory system, water spray system and drum offset with the multi-function propel handle

- Machine functions with LED indicators have been independently grouped for simplified control and quick activation

- Dual side access on ROPS/Canopy machines provide operators with flexibility to mount and dismount the machine (U.S. and Canada only)

Better Fuel Economy

- Get up to 10% better fuel economy with the Cat C4.4 engine and standard Eco-mode

- The C4.4 engine provides 106 kW (142 hp) of power and meets regional emissions requirements

- Unique Eco-mode design modifies engine speed based on load requirements; high amplitude vibration utilizes higher engine speed, while static rolling conserves fuel and operates at low engine speed with even lower sound levels

Easy Vibratory System Set-up

- Five amplitude system utilizes a single frequency with five distinct amplitudes that provide excellent performance on thick lifts and rigid mix designs

- Versa Vibe™ vibratory system creates a 2-in-1 machine with four amplitudes and two frequencies; two settings for lighter hitting and higher working speeds on thin lifts; and two settings for heavier hitting and slower speeds on thick lifts and challenging mix designs

- 2-amplitude/2-frequency vibratory system automatically optimizes amplitude and frequency with a single switch for simple thin/thick lift operation

- Reach compaction goals with automatic speed control; green indicators help ensure travel speed matches correct impact spacing

Compaction Options Include Oscillation

- Oscillatory vibration on the rear drum combined with standard vertical vibration front drum delivers both performance and versatility

- Oscillation system utilizes proven pod-style eccentric weight technology developed by Caterpillar

- 2 year/2000 hour service interval helps maximize uptime and limit maintenance costs

- Durable power-transmission belt delivers 2-times the load capacity of timing belt systems leading to extended life

- Standard drum shells offer exceptional long-term life on a variety of mix designs and delivers outstanding mat texture, density, and smoothness

Ensure Mat Coverage with Compaction Control

- Pass-count and Temperature Mapping combines infrared temperature sensors with GPS mapping to keep the operator informed of current asphalt temperatures, machine position, pass-count, and layer coverage

- Compaction Meter Value (CMV) utilizes a drum-mounted accelerometer to measure the combined stiffness of the asphalt layer, base layer, and sub-base layer to indicate road structure quality beneath the surface

- Machine to Machine communication helps keep rolling patterns in sync by sharing mapped data such as CMV, temperature mapping, and pass count coverage between multiple machines

Prevent Build-Up, Keep the Drum Surfaces Wet

- High capacity water tank provides long duration between fills

- Dual water pumps provide back-up capability and alternate with direction of travel to maximize service life

- Triple filtration prevents clogs with filters located at the fill point, water pumps, and spray nozzles

- Integrated freeze protection kit (optional) provides protection in cold temperatures when machine is not in use

Boost Performance with Enhanced Visibility

- Optimize sight lines with 360 seating option; always face the direction of travel

- LED Lighting delivers excellent job site illumination while conserving energy

- Night-lighting option provides additional illumination to the ROPS/Cab, drum edges, and drum surfaces

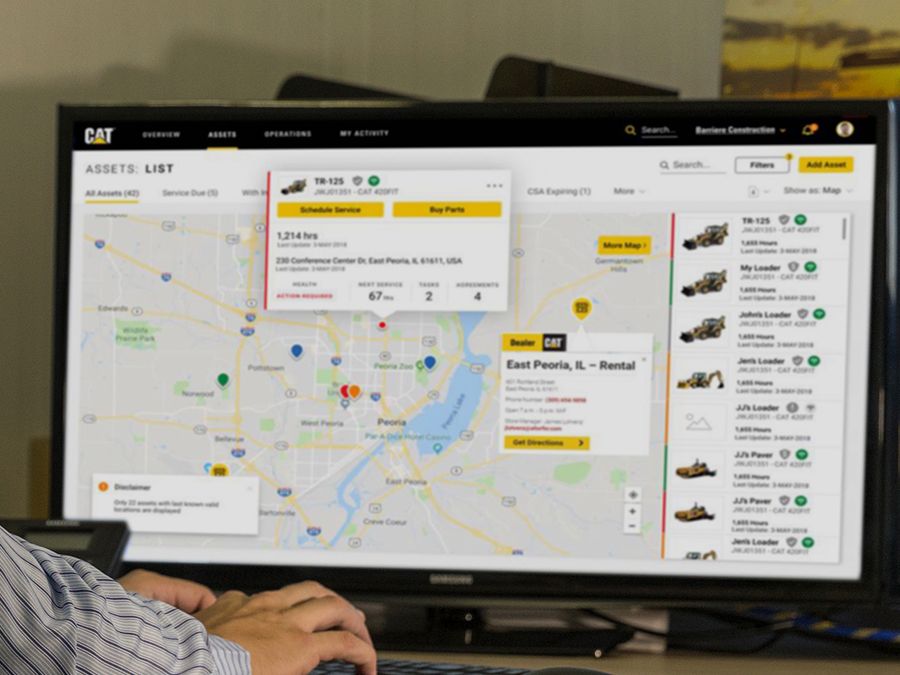

Product Link™

- Make timely, fact-based decisions to maximize efficiency, improve productivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time

- Diagnostic codes are made available through online web applications

- Remote flash works around your schedule to ensure your machine’s software is up to date for optimal performance

Standard Equipment

-

Operating Environment

- 180 degree seat positioning with sliding station

- Adjustable armrests

- Platform ROPS/FOPS

- Propel lever with 4-button control

- Steering wheel - fixed position, left side

- Suspension seat - no heat

- 76 mm (3 in) high visibility seatbelt

- Vandalism protection

-

Technology

- Product Link™ PLE743

- Remote Flash

- Remote Troubleshooting

-

Powertrain

- Cat C4.4, 4-cylinder

-

Electrical System

- 150 amp alternator

- 12-volt charging system

- Automotive-type fuse system

- Maintenance-free batteries

- Cat Electronic Technician (Cat ET)

- Remote start/charge receptacle

-

Service and Maintenance

- Maintenance-free Hitch

- 3 yr/3000 hr conventional vibratory system service interval

- 2 yr/2000 hr oscillatory vibration system service interval

- Grouped filters with ground level access

- Remote access drains

- Sampling ports for Scheduled Oil Sampling

- Site gauges

-

Safety

- Backup Alarm

- Warning horn (front & rear)

- LED Working Lights

- Steps, front drum fuel refill

- Warning, LED safety beacons

Optional Equipment

-

Operating Environment

- 360 degree seat positioning with sliding station

- Steering wheel - elevated position, left side

- Suspension seat w/ heat

- Seat headrest

-

Technology

- Infrared asphalt temperature sensors

- CMV accelerometer - front drum

- GNSS Mapping - temperature and passcount

- Machine to machine communication

- Product Link PLE783

-

Powertrain

- Offset hitch

-

Vibratory System

- Biodegradeable hydraulic oil

- Five amplitude vibratory system

- Two amplitude/two frequency vibratory system

- Versa Vibe™ vibratory system

- Two amplitude/two frequency w/Oscillation vibratory system

- Versa Vibe w/Oscillation vibratory system

- Cocoa mats

- Mats - water distribution

- Freeze protection - water spray system

- Rear drum oscillation kit - field installed drum

-

Safety

- LED Working Lights with turn signals

- LED Roading Lights

- Mirror package

- Steps, rear drum water spray refill