Technicial Specifications

| Milling Width | 1000 mm |

| Maximum Milling Depth | 330 mm |

| Rotor Speeds | 97 / 109 / 121 rpm |

| Number of Bits | 91 |

| Rated Power | 256 kW |

| Engine | C9.3B |

| Maximum Travel Speed | 7.5 km/h |

| Maximum Milling Speed | 33 m/min |

| Operating Weight | 20218 kg |

| Transport Weight | 19810 kg |

| Operating Length - Conveyor Up | 11.11 m |

| Operating Width | 2.54 m |

| Height - Canopy | 3.75 m |

| Maximum Truck Clearance | 4.7 m |

| Minimum Right Cutting Radius | 2 m |

| Minimum Left Cutting Radius | 4.23 m |

| Conveyor Swing | 60 degrees from center |

| Transport Length | 9.32 m |

| Transport Width | 2.54 m |

| Transport Height | 3 m |

| Hydraulic Tank | 55 l |

| Engine Oil | 30 l |

| Fuel Tank | 522 l |

| Cooling System | 64 l |

| Water Spray System Tank | 1260 l |

Advantages and Features

Efficient Performance

- Cat® C9.3B engine meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA and offers increased power density with improved electronic, fuel, and air systems

- Engine Idle Speed Management and multiple rotor speeds optimize output and demand on the engine

- Variable speed cooling fans operate at the lowest possible speed for optimal cooling

- Automatic load sensing on the rotor adjusts milling speed to prevent stalls and optimize production

Maneuverability and Control

- Robust propel system features dual displacement motors at each leg post, utilizing a cross-drive pattern for additional traction in straight cuts

- Automatic traction control helps reduce track slip and maintain consistent speed in the most challenging applications

- Articulating right rear leg maximizes stability and traction in demanding cuts while enhancing flush cutting capability when needed

- Optional ballast weight kit available to increase productivity in specific applications

- Wheel undercarriage offers a balance of traction, speed and maneuverability

- Ability to electronically switch between rotor speeds during operation

Highly Effective Material Removal

- High-capacity conveyors provide efficient removal of milled material with outstanding discharge control

- A wide opening and seamless belt effectively clear the rotor chamber

- Adjust the belt speed to match material type and production rate

- The belt reverses for quick clean out, while magnetic vinyl covers provide quick access to inspect and clean the rollers

Durable Cutting System

- The rotor drive system features a heavy-duty dry clutch, dual stage belt drive and automatic belt-tensioning to prevent slippage

- Reinforced cutting chamber offers enhanced durability

- Hardened full length side plate skis and anti-slab shoes reduce wear and maintenance

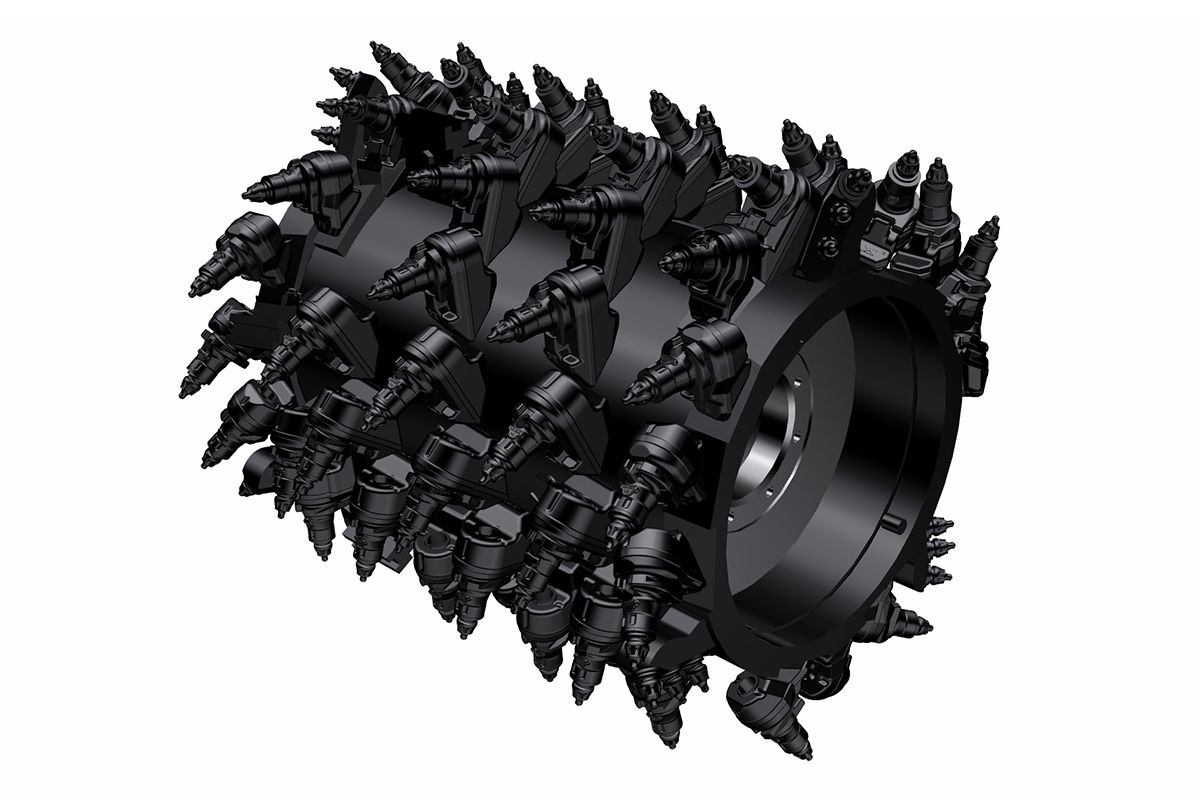

High Production System K Rotors

- Cat System K rotors feature efficient material flow with an excellent cutting pattern for numerous applications

- A tapered dual-retention design secures toolholders in place without a retaining pin, bolt or setscrew, speeding up replacement and eliminating the need for fasteners or torquing

- Toolholders, base blocks and kicker paddles are built from high strength alloy steel that’s abrasion resistant for extended life

- Optional diamond bits can extend replacement intervals up to 40 times longer than conventional carbide bits

Comfortable Work Environment

- Operate in comfort with a standard suspension seat, adjustable right arm console and intuitive, ergonomic controls

- A sliding operator station extends up to 215 mm (8.5 in) to provide improved visibility to the cutting edge

- Work day or night with backlit keypads and illuminate the work area around the machine with wide-dispersion LED or halogen lighting options

- Touchscreen displays provide access to gauge cluster, operating information, grade and slope, remote camera feeds, machine controls and diagnostics

- A 14-button ground level keypad and optional touchscreen display gives supporting personnel access to adjust leg height, side plates, moldboard, water spray and lighting

- Connect up to four optional remote cameras to enhance visibility to the cutting edges, conveyor, and rear of the machine

- Cut closer to obstacles on either side using optional remote cameras with adjustable on-screen guidance lines

- An optional hydraulically powered canopy with extendible wing and handrail-mounted windscreen protect the operator from sun, wind, and rain

- Better direct exhaust up and away when milling close to buildings or ground personnel with the optional and stowable exhaust diverter

- Maximize dust removal from the working areas with the optional dust abatement system

Integrated Cat Technology

- Achieve accurate, repeatable and automatic cutting precision with the integrated Cat GRADE with Grade and Slope system

- The optional grade control display can be positioned in the operator station or on the back of the machine to enable interaction with the grade system from the ground level

- Obtain full control of grade and slope from any machine display

- Easily adjust grade control values and sensors through the highly intuitive touchscreen interface

- Adjust the speed at which the rotor drops into the cut for optimal machine control

- Set and automate transitions into/out of cuts and save settings for future jobs

- Clear obstacles in the cutting path with ease using the obstacle jump feature

- Enhance for full 3D milling operation (additional hardware required)

Simplified Service, Low Maintenance Costs

- Maintenance is easier with large service doors for access to critical components

- Maintenance-free track components and easy to replace track pads lower service costs

- Standard ground-level controls and an optional hydraulically operated rotor turning device simplify bit removal and replacement

- The accessory drive system allows use of select machine fuctions when the engine is turned off

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, abrasion-resistant nylon braid for longer life

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 6000 hours hydraulic oil and 12000 hours coolant

- Multi-piece, cartridge-style engine filters are environmentally friendly, reducing waste and lowering replacement costs

- Electronic Control Modules (ECMs) monitor machine systems to alert the operator of performance issues

- VisionLink® takes the guesswork out of managing your entire fleet–regardless of size or equipment manufacturer*–by providing maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, and more through interactive dashboards on your mobile device or desktop, helping you make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite

- Remote Flash allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient, increasing your overall operating efficiency**

- Remote Troubleshoot allows your Cat dealer to perform diagnostic testing on your connected machine remotely**

- Convenient parts availability, dealer locations and service repair kits simplify ordering of high wear components

* Data field availability can vary by equipment manufacturer and is provided through an application programming interface (API).

** Must be within cell range coverage.

Sustainability

- Cat C9.3B engines meeting Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA, are compatible with diesel fuel blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Engine Idle Speed Management helps maximize fuel efficiency and reduce greenhouse gas emissions by elevating engine speed to an intermediate idle to complete specific tasks and returning to low idle when finished.

- Automatic Load Control helps you save fuel and reduces greenhouse gas emissions by automatically matching milling speed to engine load for maximum production at peak efficiency.

- Standby/Resume pauses major machine functions and lowers engine speed to conserve fuel and helps reduce greenhouse gas emissions during truck exchanges.

- Traction Control maintains consistent traction to increase machine efficiency, helps reduce fuel burn and greenhouse gas emissions.

- Cat Scheduled Oil Sampling (S•O•SSM) Services helps reveal excessive wear, contaminated fluids or other “unseen” issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

- Cat Grade with Grade and Slope for cold planers allows for accurate material planning to help reduce overages during the paving process and increase final project quality for a longer lasting road surface.

- Don't waste fuel idling. Cat VisionLink online fleet monitoring helps you manage idle time and reduce fuel burn and greenhouse gas emissions.

- VisionLink displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

* Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

Standard Equipment

-

OPERATOR ENVIRONMENT

- Sliding operator station

- Suspension seat

- Ergonomically adjustable arm rest

- Ground control keypad

- High-resolution LCD touchscreen display

- 12-volt power receptacle

-

CAT CONNECT TECHNOLOGY

- Remote Flash

- Remote Troubleshoot

- Cat Grade with Grade and Slope

- VisionLink® telematics

-

ROTOR SYSTEM

- Automatic plunge-cut

- Automatic grade and slope transition feature

- Obstacle jump

- Three cutting speeds

-

POWERTRAIN

- Engine Idle Speed Management

- High capacity cooling system

- Automatic Load Control

-

HYDRAULIC SYSTEM

- Traction control

-

SERVICE AND MAINTENANCE

- Ports for Scheduled Oil Sampling (S·O·S℠)

- Platform-level engine oil dipsticks

- 1260 L (332.9 gal) onboard water tank

- Side water fill valve

- Water spray system

-

SAFETY AND SECURITY

- Platform handrails

- Signaling/warning horn

Optional Equipment

-

OPERATOR ENVIRONMENT

- Additional high-resolution LCD touchscreen display

- Powered canopy

- Windscreen

- Exhaust diverter

-

CAT CONNECT TECHNOLOGY

- Sonic grade control sensors

- High-resolution LCD touchscreen display (for ground level grade controls)

-

CONVEYOR

- Dust abatement system

- Hydraulic folding conveyor

-

ROTOR SYSTEM

- Rotor turning device (with pendant control)

- System K Rotor - Coarse (18 mm)

- System K Rotor - Standard (15 mm)

- System K Rotor - Fine (8 mm)

- Diamond bits

- Pneumatic bit removal tool

- Tool holder extractor

- 510 kg (1124 lb) ballast kit

-

HYDRAULIC SYSTEM

- Cat Bio HYDO™ Advanced biodegradable hydraulic oil

- High ambient hydraulic oil

-

SERVICE AND MAINTENANCE

- Air compressor

- Accessory drive system

- High pressure washdown

- Low pressure washdown

- Additional water spray system (dust control)

-

SAFETY AND SECURITY

- Halogen work lighting

- Wide dispersion LED work lighting

- Warning beacon (fixed)

- LED roading lights

- Truck signal lights

- Remote cameras (rear back up, front conveyor, left and/or right cutting edges, magnetic mount)